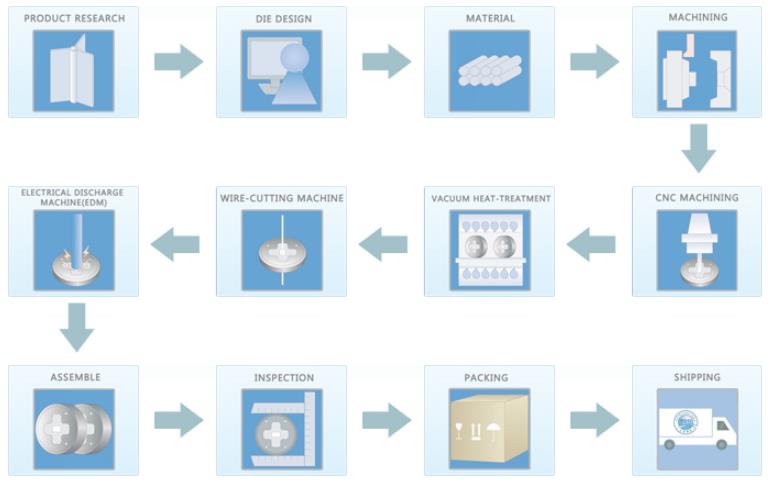

Design and development

With more than 20 years of design experience, the design team will not only pay attention to the success rate of the die, but also fully consider the situation of the extruder, improve the extrusion speed and increase the output of single machine.

Mould material

The company selects kda1 steel produced by Japan koshhva Steel Co., Ltd. to make the mold. Its good heat fatigue resistance, softening, toughness and wear resistance can improve the service life of the mold and reduce the cost of the mold. The company carries out spectrum, flaw detection and mirror image analysis and inspection on the steel entering the factory every time to ensure that each material used is qualified.

CNC machining

CNC machining center is used to complete the automatic processing of the whole mold, which ensures the quality of the mold, improves the production efficiency, and ensures the identity of the mold and the design.

Heat treatment

In order to ensure the quality of the mould, Yongxin adopts a fully computer-controlled vacuum heat treatment quenching furnace and processes the mould according to the heat treatment process approved by koshhva of Japan.

Slow wire cutting

Slow wire cutting process, to avoid the instability of manual polishing, is one of the most important equipment in the process of mold making.